Kwinana Power Plant

In 2006, Verve Energy had, through the asset management department of Kwinana Power Station, contracted a consultancy company for advice on their antifouling methodology for its cooling water system. This has been done by optimizing its chlorination procedure by means of implementation of the Pulse-Chlorination® principle. Onset for the project was the commissioning of station Cockburn Stage 1 (CKB Stage 1). To implement Pulse-Chlorination, a series of tests needed to be conducted on site. The main purpose of these tests was to determine the most effective chlorine dosing intervals and concentration to mitigate mussel fouling.

Project facts

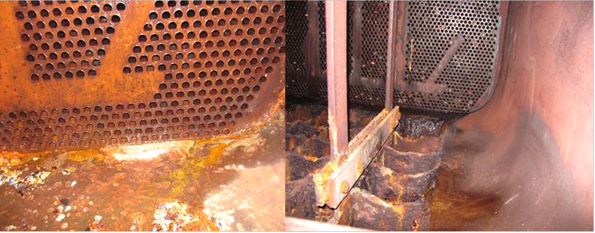

The advised Pulse-Chlorination regime had been implemented by Verve Energy during spring 2006. During the first year of implementation, several inspections of the cooling water system have been carried out by divers. From the observations by the divers and the results of the inspection of the condensers in August 2007, it could be concluded that the advised Pulse-Chlorination regime was effective against macro fouling at Kwinana Stage C and CKB Stage 1. These results were confirmed by the results gained from the Biofouling Monitors which monitored the efficacy of the chlorination throughout this period.

During the inspections of the cooling water intake channels, some growth of mussels was noticed at the first part of the channels and the rest of the cooling system was clean. It was found that this was the result of inadequate mixing of hypochlorite with sea water that enters the cooling water intake channels. To improve the effectiveness of hypochlorite dosing, a new chlorine dosing structure is being redesigned and optimised by applying Computational Fluid Dynamics (CFD) modelling of the injection interface to ensure optimal mixing.

Project aim

The aim of this project was to achieve an effective dosing regime for the CKB-1 and KPS Stage C power stations, as an alternative to heat treatment. Therefore, the technical possibilities hereto were investigated.

Solution

The outcomes of this study have been published:

OPTIMISATION CHLORINATION STRATEGY SERVICE WATER SYSTEM.

H.J.G. Polman., Bruijs, M. C. M., Calneggia F. and Jenner H.A. Optimisation chlorination strategy service water system Verve Energy’s Cockburn and Kwinana power plants. – Presented at the API POWERCHEM 2008 “Power station Chemistry solutions for the 21st century”. May 2008 Australia.

Please contact us and we will send you the full article.

Results

During a planned maintenance overhaul in July 2007 of KPS-6, the condenser was opened for inspection and maintenance. It was observed that the condenser was very clean. There was no mussel or barnacle, only a small number of empty small mussel shells in the return water box.

Other Case Studies

REFINERY IN ROTTERDAM HARBOUR, THE NETHERLANDS.

UNIPER MAASVLAKTE POWER PLANTS